Steel Industry

Removal of Slag and Brick from Ladles

Occasionally, a ladle will be red-hot during the slag removal process. As such, the job must be completed in both a safe and timely manner. One must act with caution when removing slag from ladles or risk damaging it, making precise and powerful tools a necessity.

Brokk demolition robots allow operators to move freely around the machine, allowing them to get the best angle of sight without compromising personal safety. Using a remote control, operators can avoid vibrations, gasses, and the risk of fire from the safety of a shielded cabin. Brokk’s three-part arm system is well suited for challenging operations due to their ability to work horizontally and reach nearly every angle within the ladle.

When a ladle is not too hot, bricks can be removed from the inside. At this time, the main concern is to avoid damaging the ladle shell and safety refractory linings, as well as maintaining the safety of workers from falling debris and saving time.

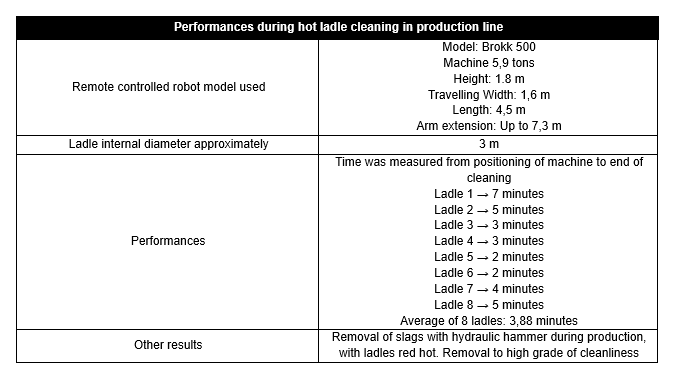

Tab. 1 – Remote demolition robot performances during removal of slags from red hot ladles, in production line. Feralpi steel plant, Lonato del Garda, Italy.

Bricks removal in torpedo cars

Torpedo cars are typically long and cylindrical, with extremities that taper off at each end and small manholes located in the center. They are lined with refractory materials that need to be replaced when the material is worn-out. Because access points are generally very small, a Brokk is the perfect machine for the job.

Small remote-controlled demolition robots are applied in this case because they can access the torpedo car while carrying a heavy-duty hydraulic hammer, all while generating no emissions. Our robots can access the torpedo while operators can work from a safe location. The time required to remove a torpedo car can be significantly reduced by a Brokk machine, as opposed to removal by manual labor or other excavators.

Brick Removal in Electric Arc Furnaces (EAFs)

An electric arc furnace is generally lined with refractory brick, while the bottom is made of castable refractory. Brick removal can sometimes be partial (allowing for repairs), while other times it may be necessary to totally tear out the interior. This is dependent on operations and the condition of the brick.

In both cases, access to the furnace is limited by its size or by the design of the plant. Operations are performed when an EAF is still hot, with temperatures around or over 120° F, a dangerous environment for operators and other excavators.

Small Brokk machines can be lifted into an EAF, often on a platform, while larger Brokk machines are operated from the outside. In both cases, operators are placed outside at a safer distance from high heat and dust.

Slag and brick removal in converters

There are many types of converter mouths, brick retention rings and grids, tap hole positions, and degrees of ease of access to working sites. Brokk has a machine for any occasion.

For the cleaning of large converters, Brokk robots remove slag using a rotating (or revolving) boom and a hydraulic hammer. Operations must be conducted with care and precision to avoid damaging any lining. For smaller converters, the standard booms on Brokk machines can get the job done.

Slag and brick removal in tundishes

A tundish is a container located between a ladle and a mold. It is used to transfer liquid steel from the former to the latter. Tundishes are typically lined with refractory or castable that need to be replaced from time to time.

The tear-out process is typically completed using hydraulic hammers. Brokk robots are an efficient option for this job because they can reach into a plant with ease and move through hazardous areas without risking the safety of the operator, while still allowing them to overview the job and make certain that the chisel is not doing any damage to the tundish.

Taphole drilling

Molten iron is tapped from furnaces into ladles or runners through tapholes. Therefore, a taphole is exposed to hot liquid metal several times a day, depending on the size and design of the attaching furnace. Brokk machines have the flexibility required to clean tapholes using specialized tools and/or conventional chisels. Brokk machines can be used for converter tapholes or for cleaning EAF tapholes (EBT).

porous plug removal

A porous plug is a refractory nozzle that is installed in the base lining of a ladle. This enables the introduction of gas, which generates a stirring action within the molten metal. Porous plugs need to be replaced; a job typically done during production when the ladle is hot.

Brokk robots be equipped with specialized chisels that allow the operator to push out a plug through the bottom of a ladle. Thanks to the precision of the machine, porous plugs can be pushed out in under 60 seconds. Brokk machines are ideal for this application, as they can withstand very high heat and complete the task in a timely manner.

Refractory Removal and Cleaning of Pelletizing Kilns

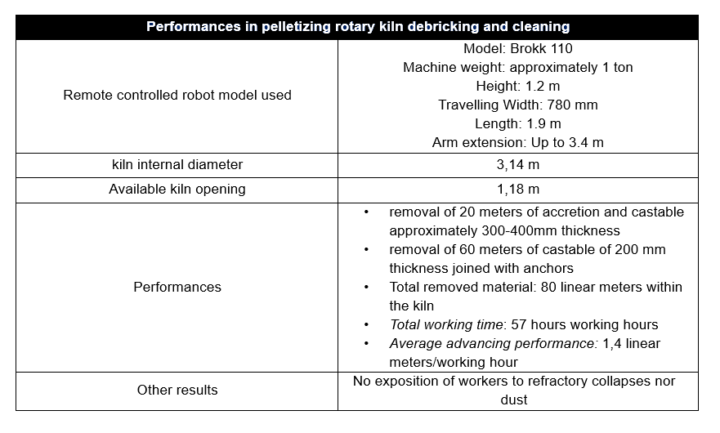

A rotary pelletizing kiln is a cylindrical structure that slopes downwards slightly which a length of 165 feet or more. Its inner diameter can be anywhere from 6.5 to 15.5 feet across. Maintenance includes removal of refractory and slag.

The main advantage of a Brokk machine in this context is the safety of the operator, who never has to be placed under overhead refractory or coating, which has a risk of falling. Furthermore, the tear-out time is reduced significantly compared to conventional methods, increasing plant productivity. Brokk machines are designed to work in hot and dusty areas such as this without the risk of breaking down.

blast furnace

Blast furnaces are large structures that range in size from 65 to 115 feet in height and feature hearths with diameters of 18 to 56 feet across.

Brokk robots are often used for a number of tasks inside of blast furnaces and can be used for breaking up refractory and slag. Because our robots are built to be heat resistant, the job can begin earlier than with conventional excavators.

runner cleaning

Runners are used to transfer iron from a blast furnace into a torpedo. These runners are often lined with refractory or castable that need to be removed.

Brokk robots are perfect for this application, as the machine can get close to the runner and the operator can overview the breaker from any position. As the Brokk robot can change tools quickly, they can be used for breaking, trimming, and excavating as well.

Brokk robots and booms can withstand high temperatures that allows the operator to begin work while the runner is still very hot.

Thank You!

Thanks for your message. We’ll answer as soon as possible!

// The Brokk team